Page 3 of 4

Re: MY FIRST CADET

Posted: Sun Jan 31, 2016 12:32 pm

by DuncaninFrance

Re: MY FIRST CADET

Posted: Sun Jan 31, 2016 1:17 pm

by dhtaxi

Interesting. How difficult was it to turn the barrel of.

Re: MY FIRST CADET

Posted: Sun Jan 31, 2016 2:19 pm

by DuncaninFrance

dhtaxi wrote:Interesting. How difficult was it to turn the barrel of.

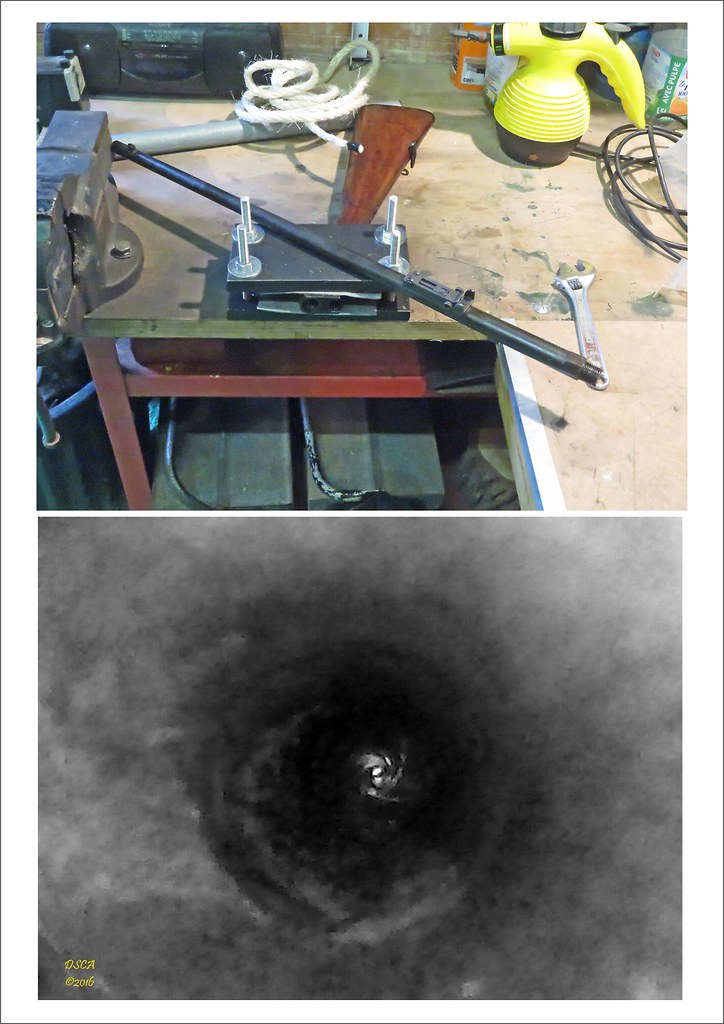

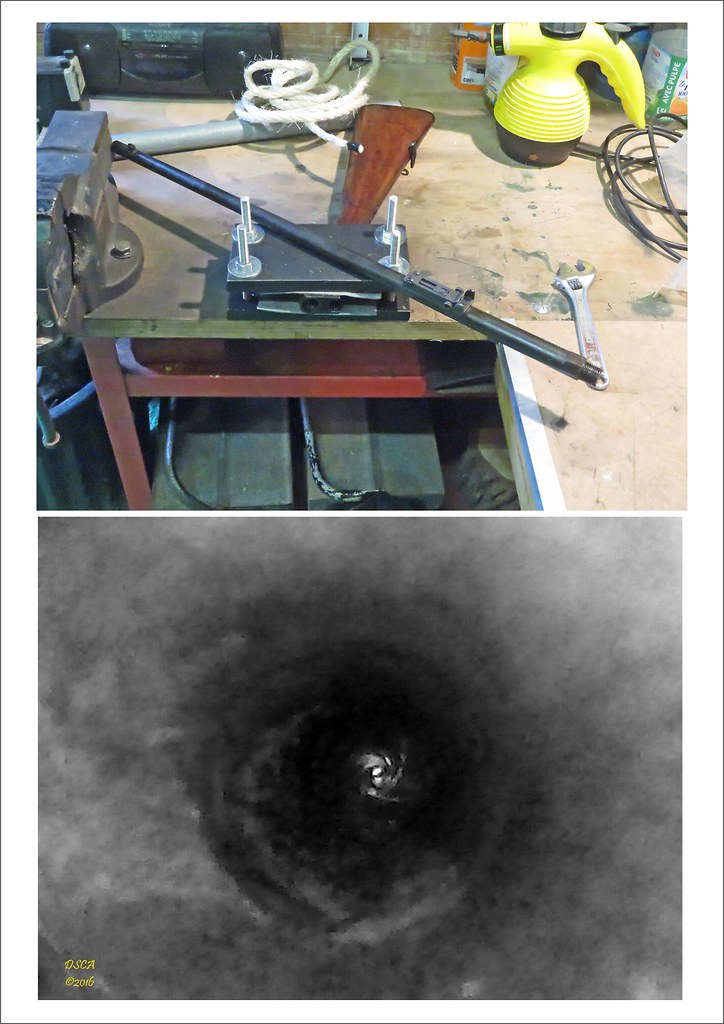

Not difficult Dave, it's the principal of leverage, just need a long enough stick

It MUST be a natural fibre, synthetics don't work. Needs an 8' length and should be about 10mm dia.

Re: MY FIRST CADET

Posted: Tue Feb 02, 2016 6:41 am

by DuncaninFrance

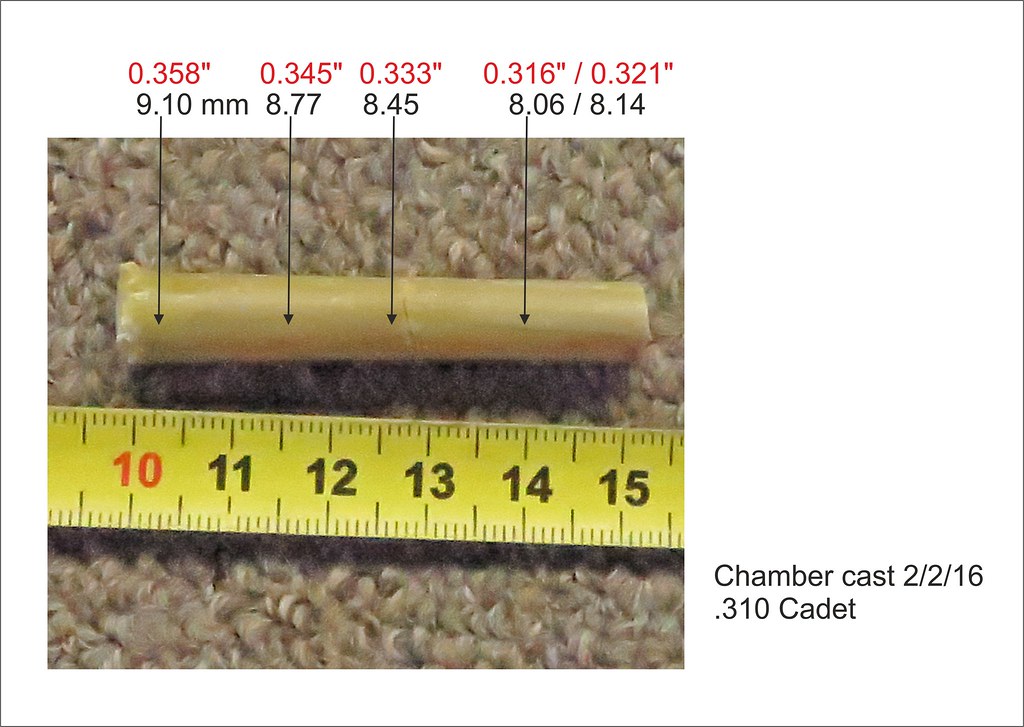

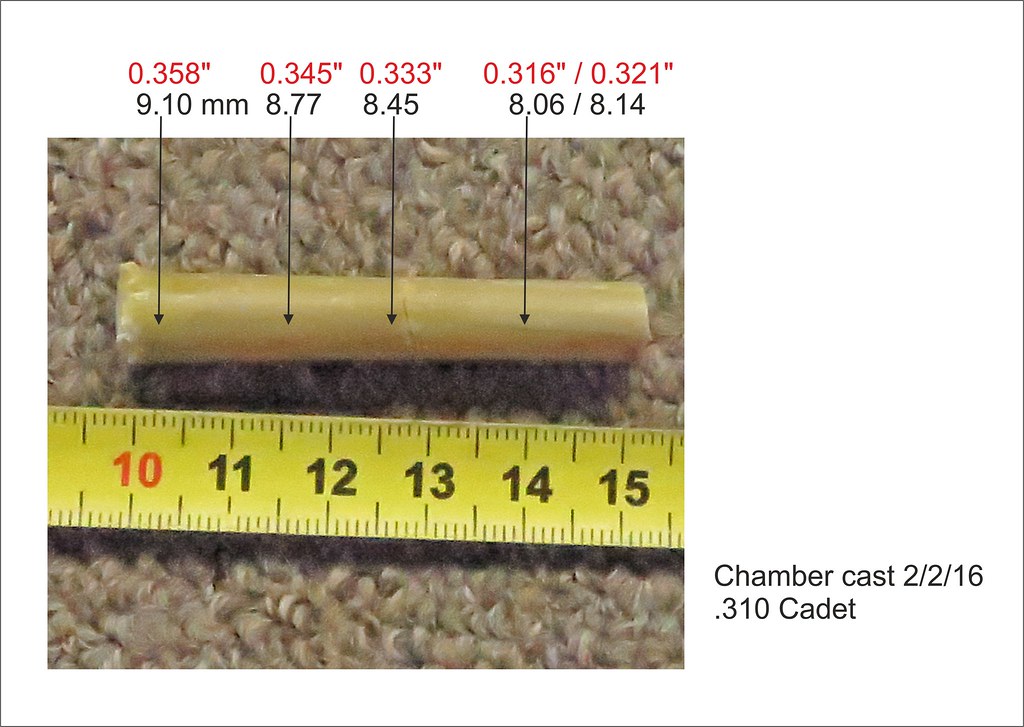

Managed a chamber cast this morning - easy when you know

how milsey: embarassed

Re: MY FIRST CADET

Posted: Sun Feb 07, 2016 1:30 pm

by ArchFluffy

This thread is great!

I wish all this work were not needed though.

-ArchFlffy

Re: MY FIRST CADET

Posted: Sat Feb 20, 2016 11:49 am

by DuncaninFrance

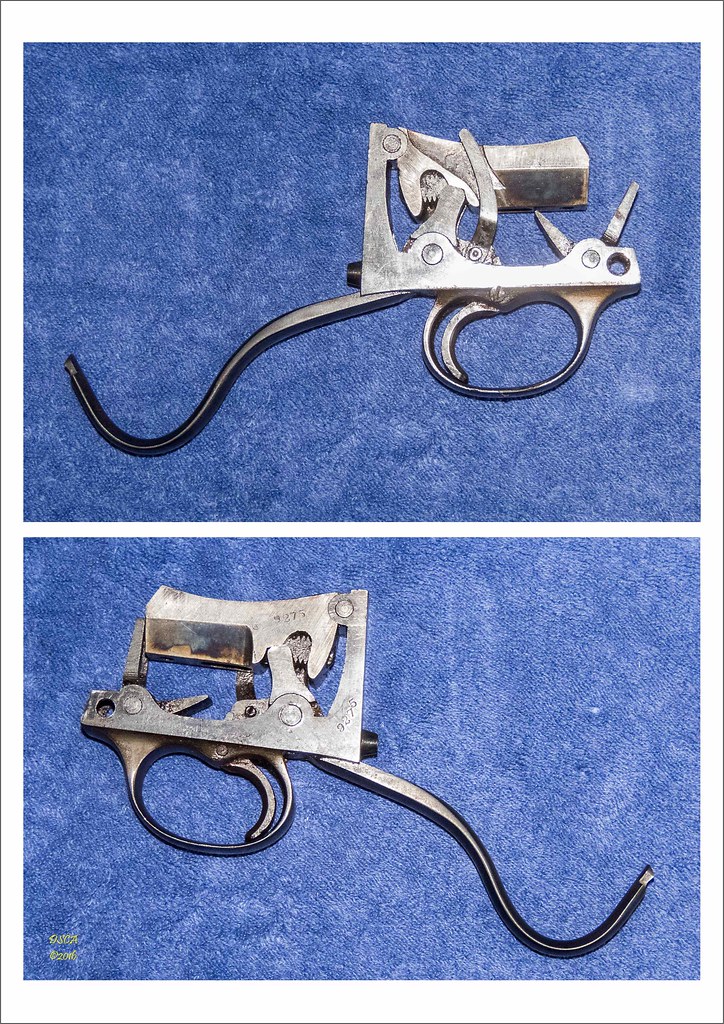

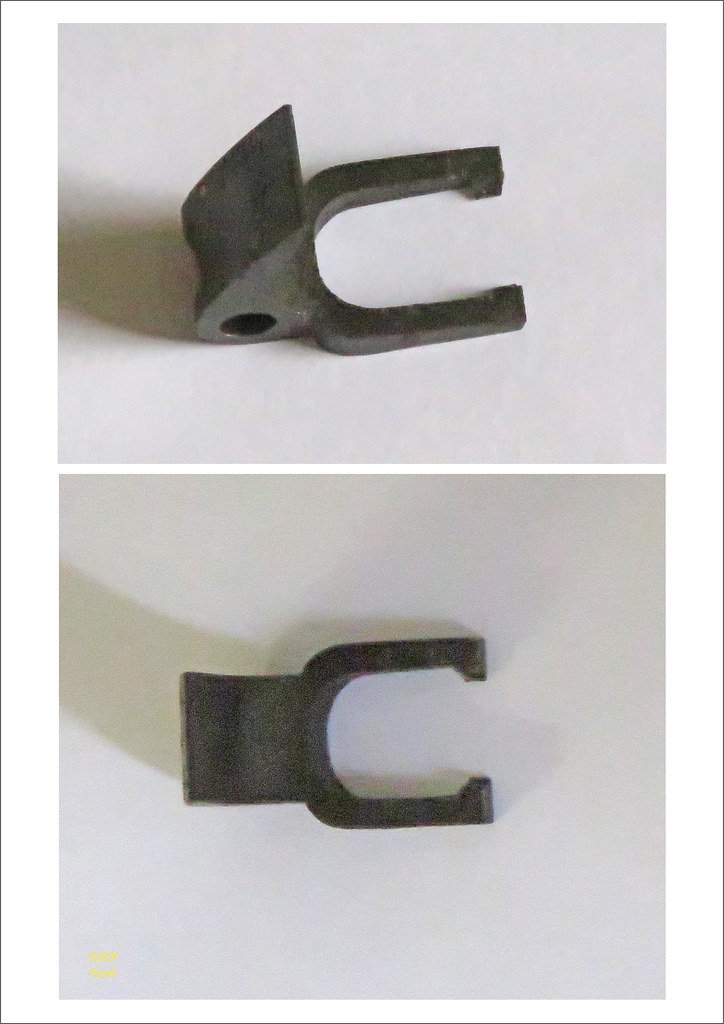

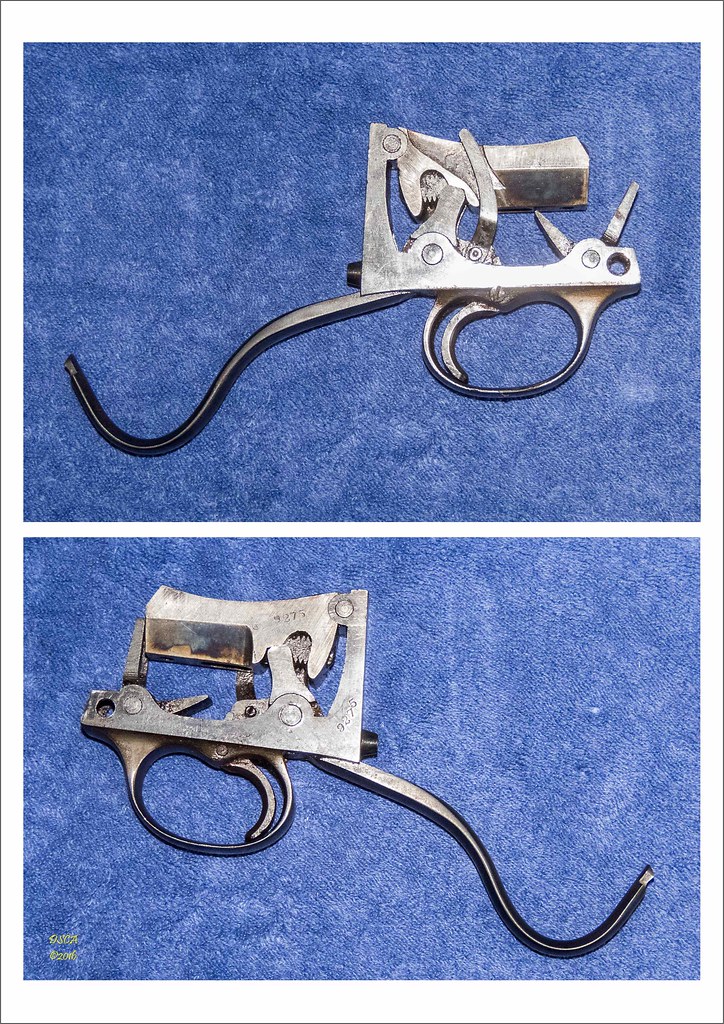

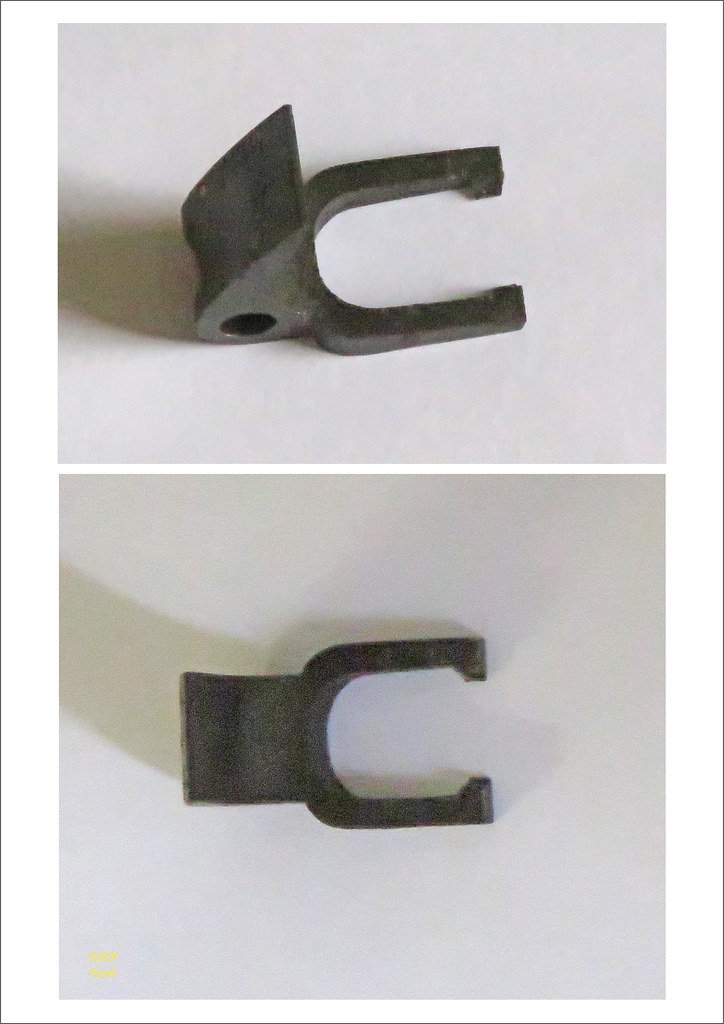

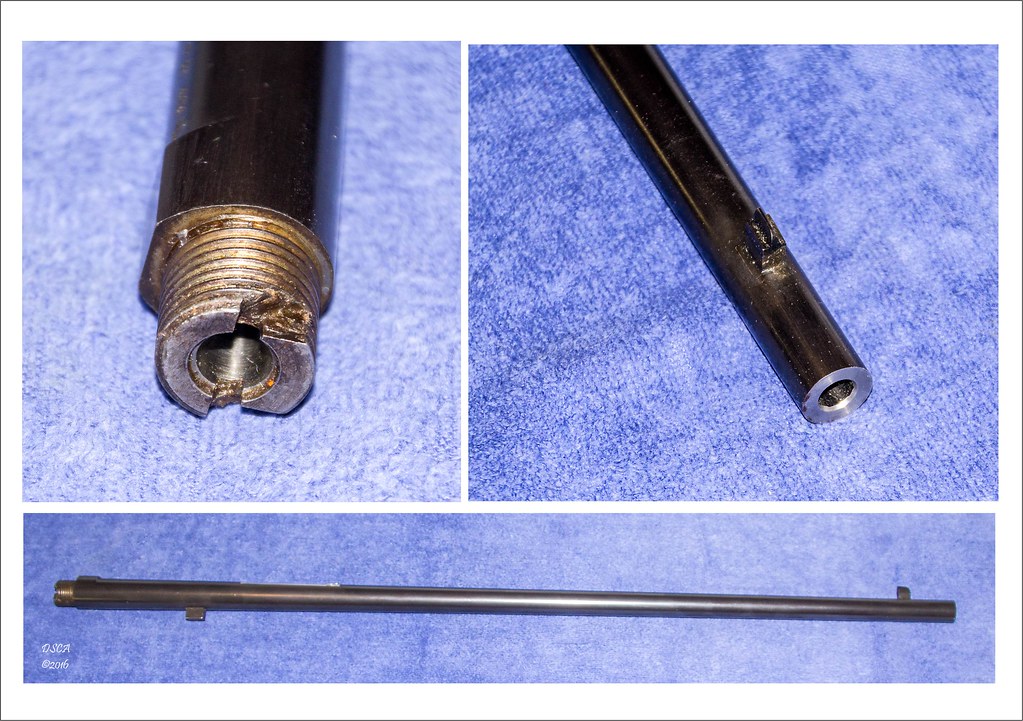

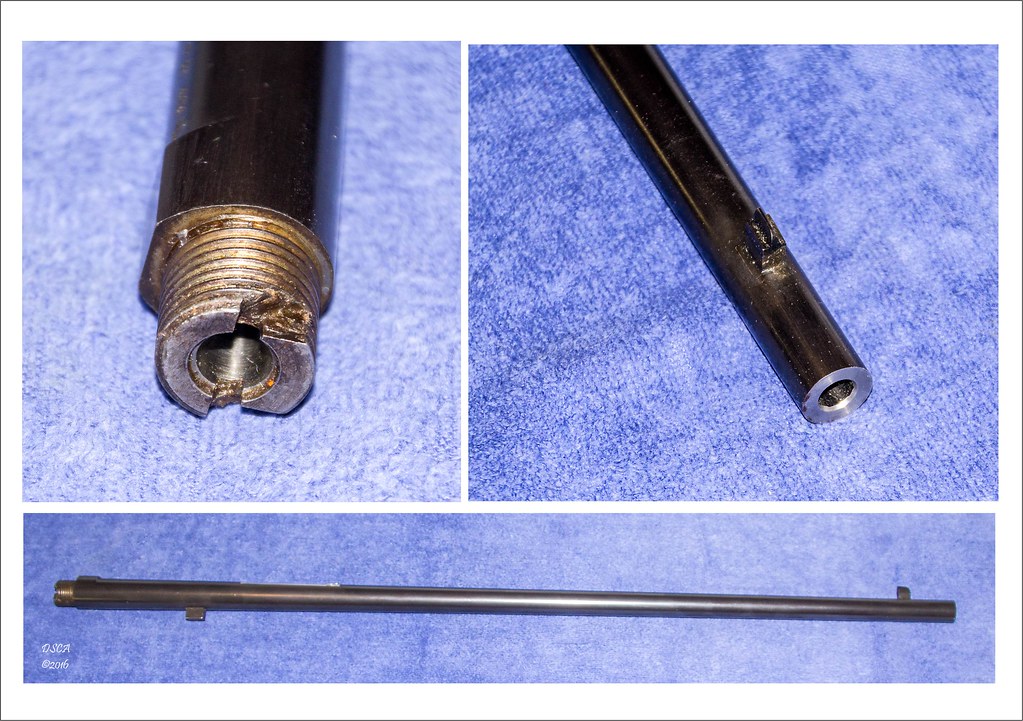

Well, there is more than one way to skin a cat as we all know. This little gem arrived in the post yesterday...............

I hope to mate it with a certain action tomorrow all being well............

Re: MY FIRST CADET

Posted: Sun Feb 21, 2016 1:45 pm

by DuncaninFrance

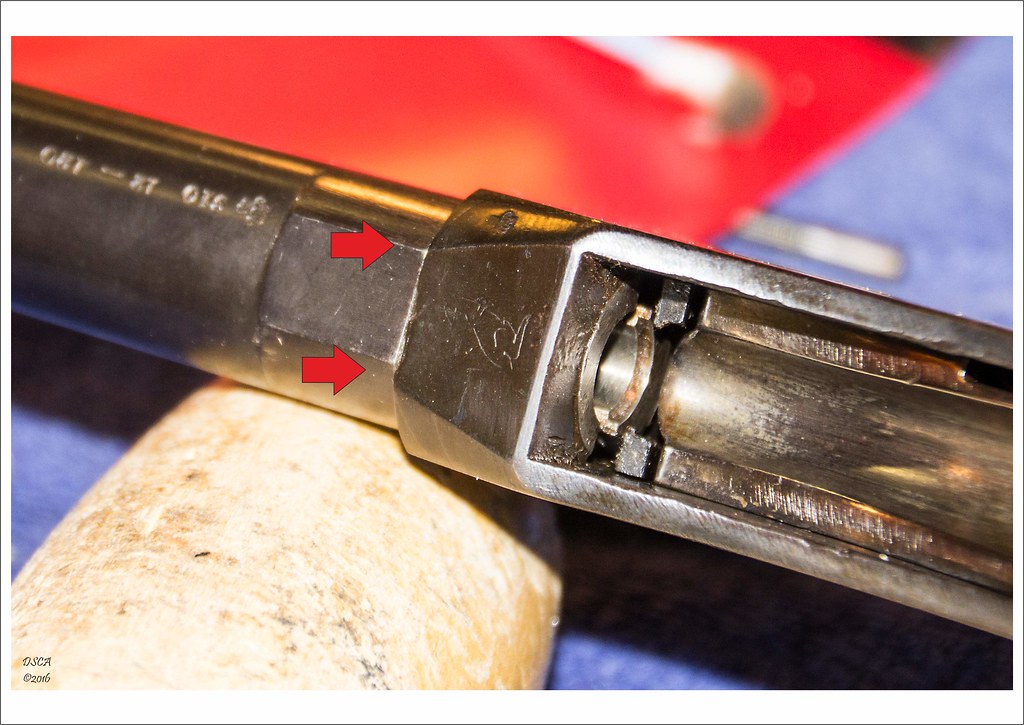

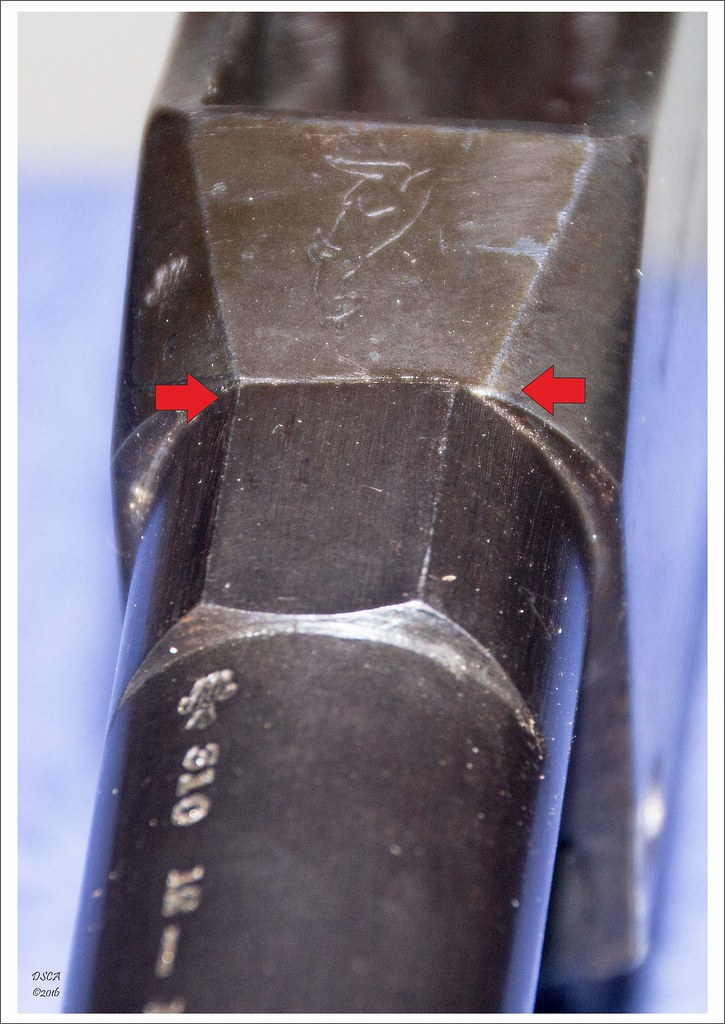

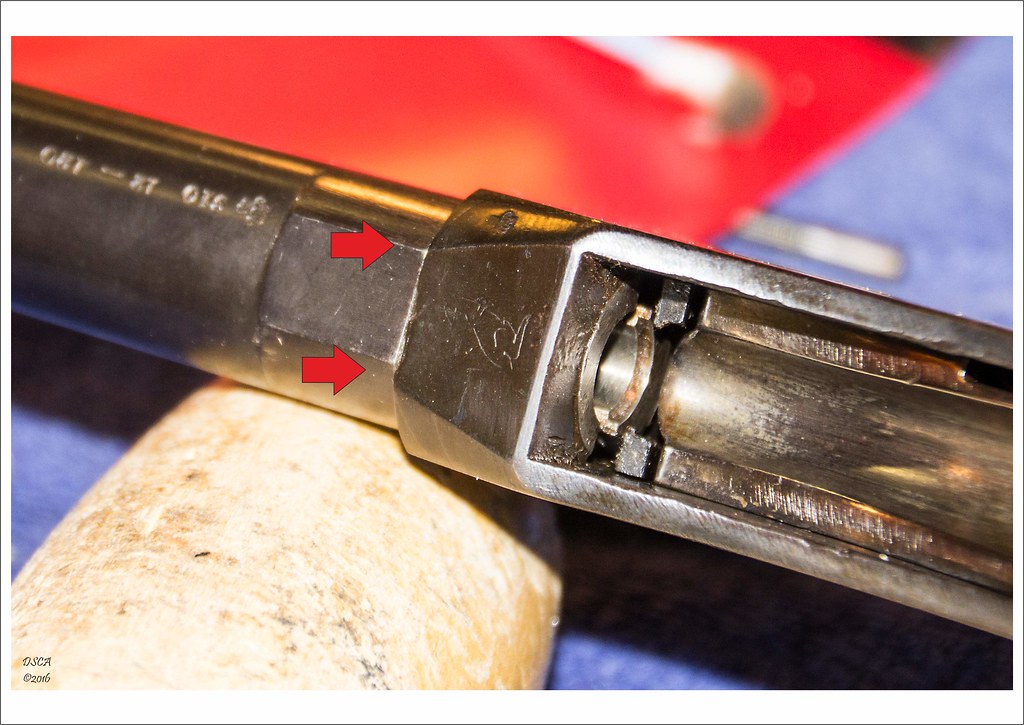

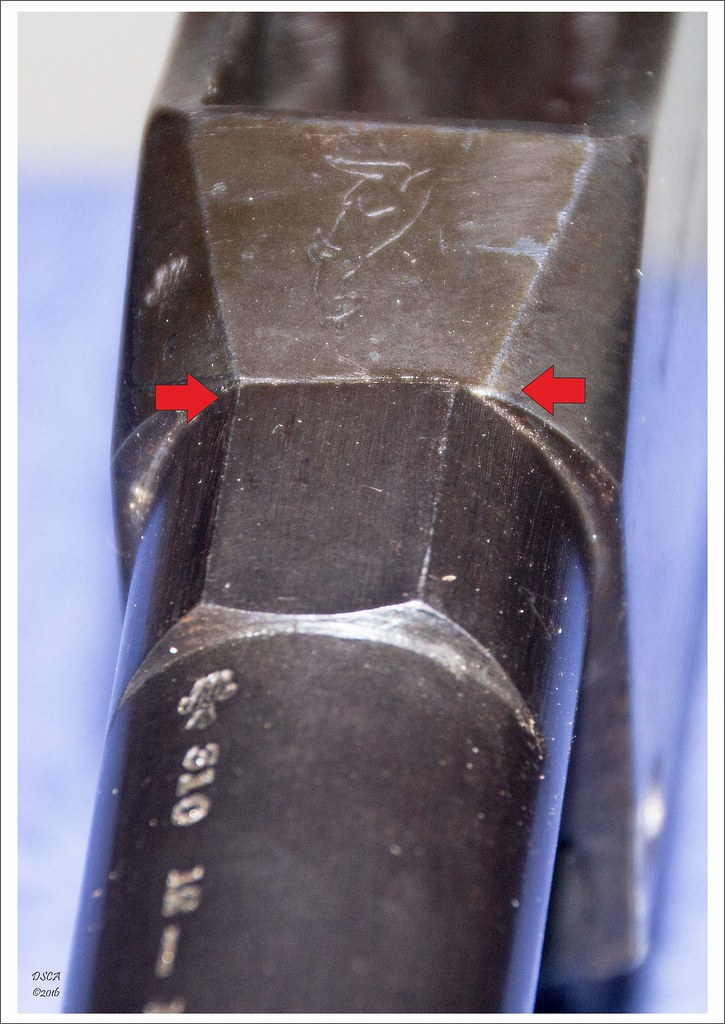

Tried fitting the new barrel to, my Cadet today but I am having the devils own job to get it fully screwed home. This means of course that I can't close the breech properly even though the extractors seem to locate in the slots.

Before starting the barrel I lubricated the thread with a small amount of silicone grease as used on shotgun chokes - is this a possible reason?

As usual. any advice etc.,................

Once it is in situ I need to drill and tap a hole to take the rear furniture screw.

Suggestions on a €20 note to..............................

Re: MY FIRST CADET

Posted: Sun Feb 21, 2016 2:32 pm

by Niner

Reminds me of the time I tried to replace a nipple bolster on a BP rifle. Seemed an easy task. I ended up buying more than one bolster because when screwed into the side of the barrel where the original one went it would tighten up with the nipple hole offline with where it needed to be.

Re: MY FIRST CADET

Posted: Mon Feb 22, 2016 6:29 pm

by dhtaxi

Duncan has you have just found out fitting a new barrel is not just a matter of buying a chambered threaded barrel.

The barrel thread has to be cut to fit the action. The barrel has to be chambered to the correct head space. Otherwise you can blow the gun up or hurt your self.

Your new barrel is clearly not threaded to the action it needs to go in the lathe and have the thread re cut and possibly the chamber recut with a finishing reamer. Once you have done that the chamber needs checking for correct head space. The barrel needs machining to fit correctly and that is why you can not close the breech properly even though the extractors seem to locate in the slots.

What are you doing with the old barrel as a matter of interest.

Re: MY FIRST CADET

Posted: Tue Feb 23, 2016 3:44 am

by DuncaninFrance

What are you doing with the old barrel as a matter of interest.

Keeping it because it is the original and is numbered to the action