As I have said, I have a mentor in Iowa who is helping me sort this cow of a piece out

here are his comments on the photographs which I sent him.

You certain this lock was not made in Nepal?

So here goes:

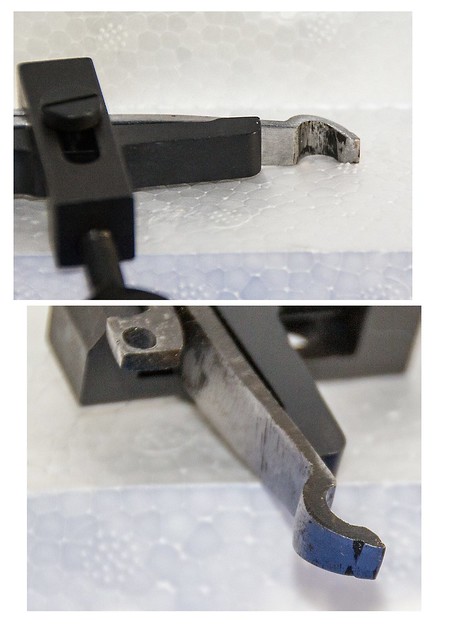

1. Grind/stone the hook on the main spring where it rubs on the lock plate.

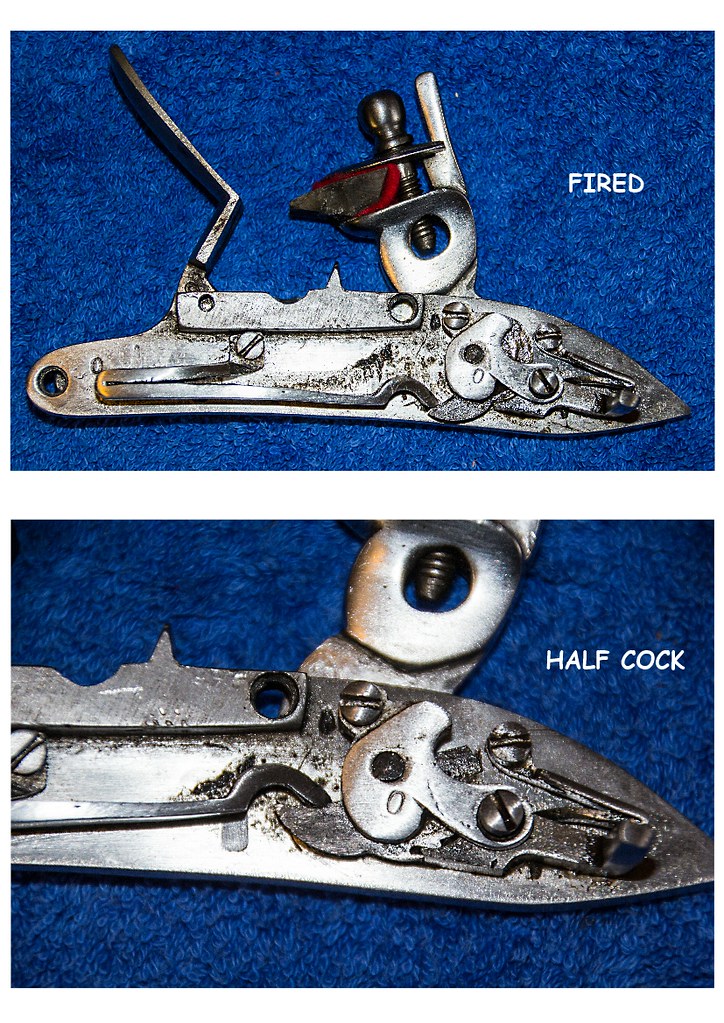

2. Ditto the tumbler. May be rubbing on the edge corners around the tumbler foot because of poor fit of tumbler shaft to plate. Check for wear against the inside of bridle.

3. Ditto sear.

4. Actually all components are scabrous and in need of some polishing or at least leveling the surfaces and removing burrs.

5. Polish off any place that shows wear. Note that any wear marks on the tumbler, sear, and frizzen may indicate poor hardening and may need to be reworked.

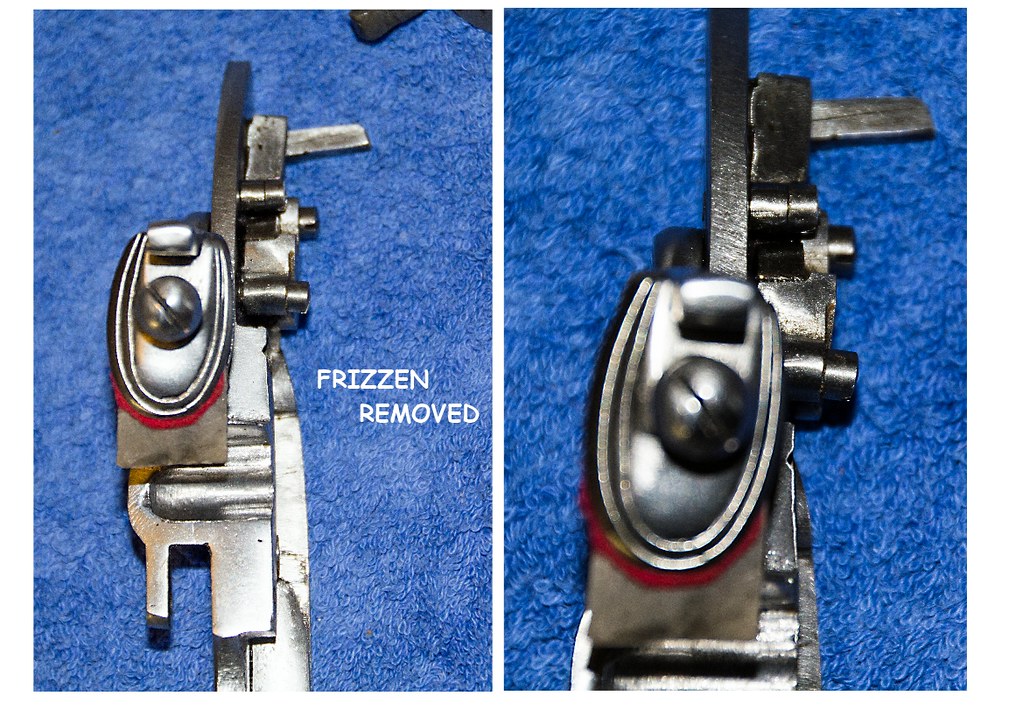

6. Make certain the tip of the sear spring does not touch the hump of the sear (which the mounting screw goes through) in any position. It should touch just behind it.

7. Smooth the inside of the lock plate.

8. Make certain there are no burrs projecting beyond the edges of their respective holes. Countersink lightly, if required. (a drill bit countersinks holes admirably.)

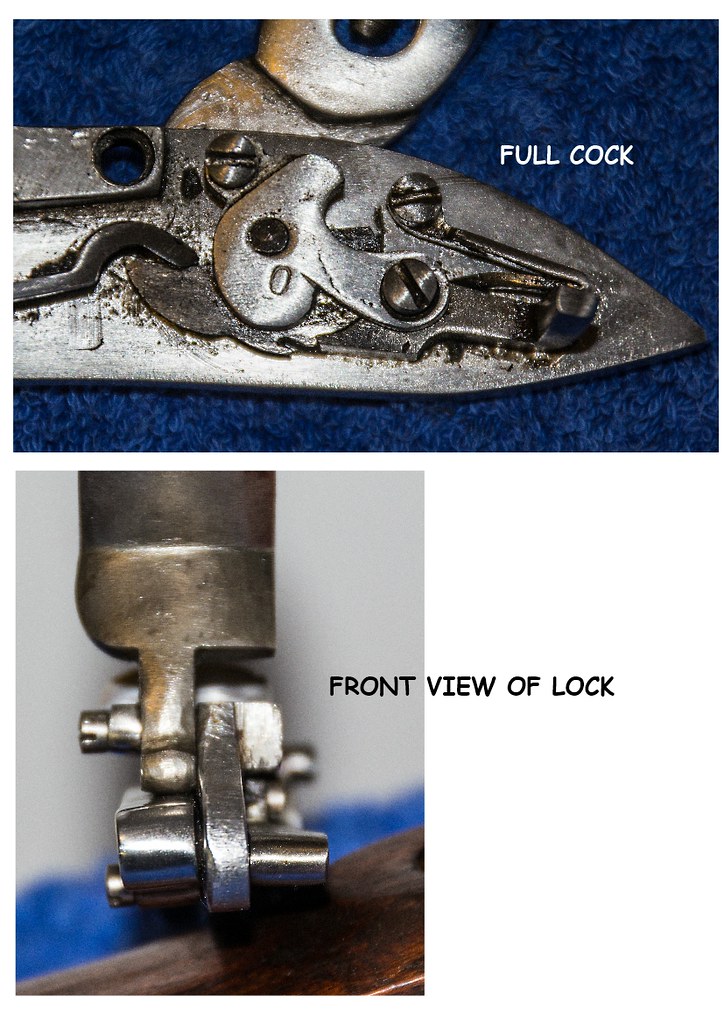

9. Sear spring appears to have cold shut- probably going to fail you later on. Do not know why there is a slot in the knee of the spring. The tip looks.......

10. Tumbler and sear must pivot effortlessly when reassembled.

11. No drag on the springs. Use grease on the tips.

12. Examine frizzen face for scuff marks. You want the flint in position to obtain the longest scratch marks possible AND throw open the frizzen from the pan.

13. There should be no hesitation of the flint to throw the frizzen open. If there is, the frizzen toe may be at fault – poor geometry. The frizzen may be dragging on the frizzen screw. The toe maybe dragging on the spring for some reason, such as metal bits or file marks, etc.

A good flint lock and flint will fire the main charge usually 1 out of 6 times without powder in the pan. A frizzen spring is not essential to fire the gun. A properly fitted and tuned flint lock will feel glass smooth when assembled and cocked. You should be able to fire the flint lock by holding it in your hand and feel little or no torque as the components go through their paces. A good flint lock can have the pan filled with powder, your thumb covering the hole where the pan fits to the vent, the lock held under running water, pulled out and be immediately fired with soaked frizzen 100% of the time. (I love showing people this.) A good flint lock will fire 100% of the time upside down.

Now that you know some of the standards, try to bring your lock into line as much as you can. Do realize this is not an exercise in futility, but yet another opportunity to make a silk purse out of a sow’s ear. One thought not discussed is that you may be able to fit Rifle Shoppe parts to your plate and thus end up with a fine functioning lock worth keeping.

So, thats the plan for now................