Page 1 of 2

Small Learning Curve............

Posted: Sun Jan 31, 2016 4:59 am

by DuncaninFrance

Re: Small Learning Curve............

Posted: Sun Jan 31, 2016 7:35 am

by Aughnanure

You'll have fun with that and it'll be great for making pins and screws and other fiddly bits.

When you graduate get a bigger machine that has a flat bed and a flat belt drive, no gearbox but change wheels and a slotted table and at least a 1.5 inch spindle hole and you'll be able to do any gunsmithing job.

Re: Small Learning Curve............

Posted: Sun Jan 31, 2016 12:27 pm

by DuncaninFrance

Thanks Eoin,

This a link to the YouTube Video of it

https://www.youtube.com/watch?v=fCxOmLLXFb4

Drive is a variable belt. 800 - 5000 RPM

Re: Small Learning Curve............

Posted: Mon Feb 01, 2016 3:27 pm

by dhtaxi

All right for small stuff but the hole through the spindle is to small for anything gun smithing. You could probably make dies on it.

Re: Small Learning Curve............

Posted: Mon Feb 01, 2016 5:37 pm

by DuncaninFrance

Like I said Dave, Small Learning Curve. It will be OK for replacement pins in my Martini's..........

Re: Small Learning Curve............

Posted: Thu Mar 24, 2016 7:54 pm

by deadin

Duncan, Duncan, Duncan..... You know not what you've done......

Next will be carbide bits, then a Quick Change tool post, followed by a collet set and on and on, ad infinitum....

Then that small bench top mill will complete your needs. (and the tooling for it never ends.)

(I know from which I speak).

Finally, bigger is better and, of course, all of the various tooling you have accumulated won't work with larger machines.

Dean

Re: Small Learning Curve............

Posted: Thu Mar 24, 2016 11:17 pm

by Aughnanure

Duncan,

Have a look at what this chap has done in NZ.

http://www.australianhunting.net/index. ... c=184481.0

Two of the good reasons for having an old style and thoroughly out of date flat bed and flat belt driven lathe are,

1) The bed is simple to true up and bring back to as new (only hard work needed).

and

2) the flat drive allows easy back and forth rotation by hand, as in milling away unwanted bits that can't be removed by full powered rotation.

Re: Small Learning Curve............

Posted: Fri Mar 25, 2016 4:03 am

by DuncaninFrance

Aughnanure wrote:Duncan,

Have a look at what this chap has done in NZ.

http://www.australianhunting.net/index. ... c=184481.0

Two of the good reasons for having an old style and thoroughly out of date flat bed and flat belt driven lathe are,

1) The bed is simple to true up and bring back to as new (only hard work needed).

and

2) the flat drive allows easy back and forth rotation by hand, as in milling away unwanted bits that can't be removed by full powered rotation.

It needs a password Eoin

Unfortunately I don't have enough room or the funds for anything bigger at the moment and this will at least allow me to practice - all be it in miniature. The last time I used a lathe of any kind was back in 1964 when I was at school

Dave; It may seem very small but it will hold a .577 case so will allow me to trim down 24G brass for my MH & Snider rifles so that is a good start................Watch this space because I am getting some professional help

Re: Small Learning Curve............

Posted: Fri Mar 25, 2016 12:21 pm

by DuncaninFrance

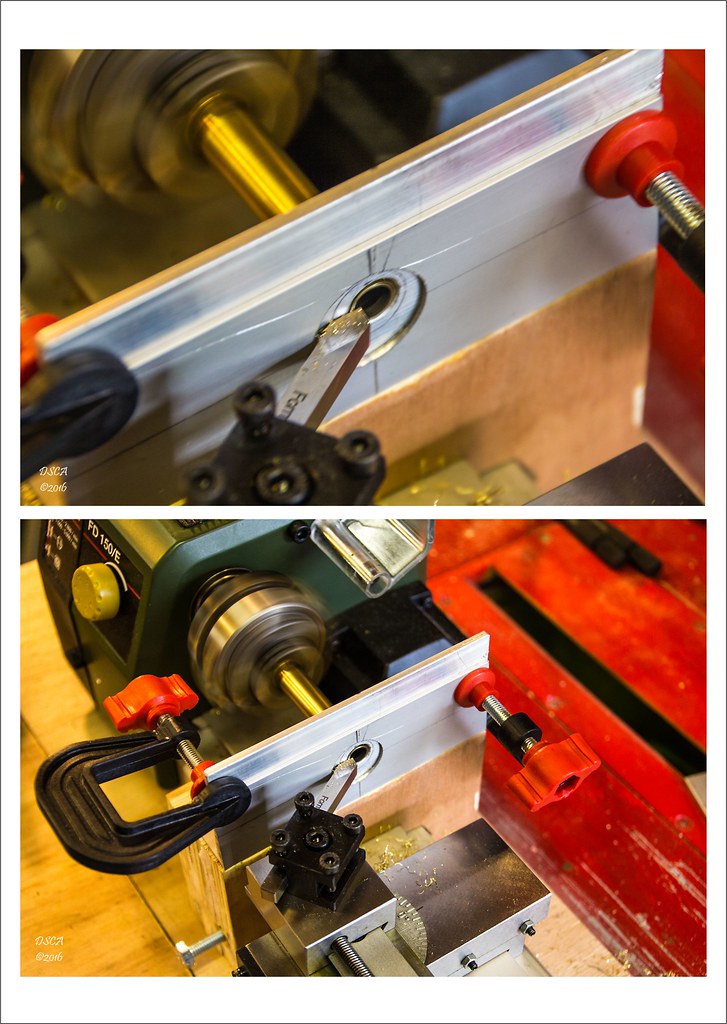

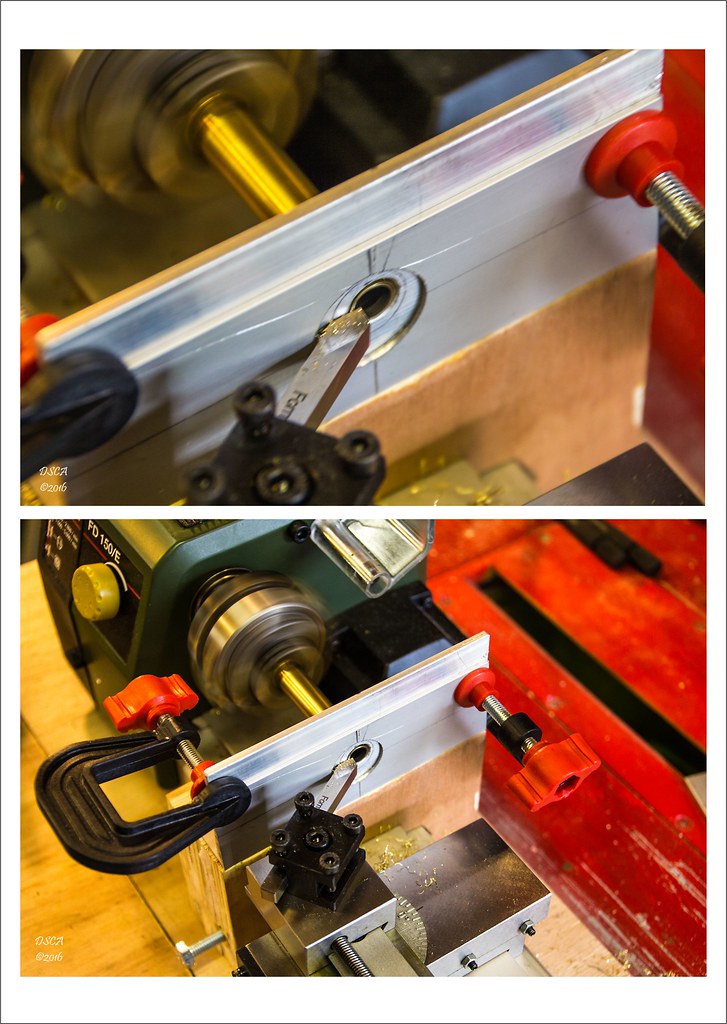

First Job............

One of the jobs that I thought the new lathe would do well was Case Trimming - particularly my .577 and .577/450 brass. I made a 'steady frame' because an 'off the shelf' one was not available. To that I attached a piece of aluminium angle with an oversized hole in the centre.

Next I made up some plates in aluminium with holes just a gnats knacker larger than the case mouth diameter. My current piece of reloading is for my .303 so I decided to give it a try.

Here is the set up.

You can see the other plates laid behind the machine.

The .303 plate was set exactly so that the case was cut to 72mm when the cutter touched the face of the plate. ( .303 Sporting )

After trimming 100 cases I found that the variance was less than .25 mm / .0098" which I am quite happy with.

Re: Small Learning Curve............

Posted: Sun Mar 27, 2016 8:53 am

by Aughnanure

Now that's constructive thinking, a professional (and I include myself!) would have designed something much more complicated